Applications Solutions

Process Piping Inspection and Assessment

Pipework is often not given the same level of inspection and maintenance focus as pressure vessels. Because of the large numbers of piping circuits on processing facilities, pipework can pose a significant risk of failure. Damage mechanisms and stress analysis can be complex, with accessibility restrictions an added challenge.

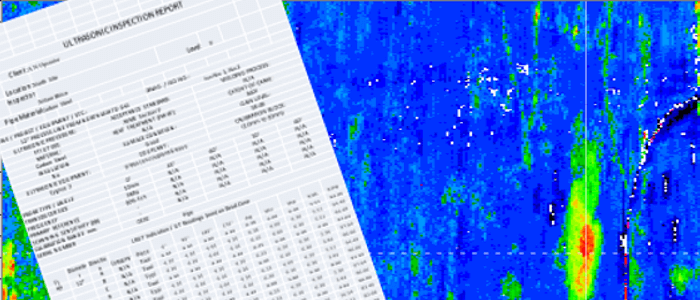

Understanding the likely and active damage mechanisms, employing a range of suitable NDT techniques and using flexible assessment tools are crucial in effective piping systems integrity management.

Examples of piping systems integrity challenges:

- Corrosion under insulation

- Corrosion at pipe supports

- Dead legs

- Difficult to predict damage, e.g. from water hammer and cavitation

- Fatigue, including vibrational and thermal

Are scheduled thickness readings at TMLs sufficient? When should we inspect pipe welds? TOFD vs AUT vs MFL? Are there reliable condition monitoring systems for high risk locations? Can we rapidly screen long inaccessible lengths?

We'll help you answer these questions and more. Email us or give us a call.

By the Book

NDT procedures and guidelines

Selection of NDT techniques, development of method statements, validated procedures with representative test pieces, and guidelines.